Preparing the doorway correctly is essential for a safe, precise, and seamless lift installation. Every opening must match the signed Lift Shop Final Drawing and be built to withstand structural loads, align with finished floors, and suit the final wall finishes. This guide outlines everything your builder needs to prepare before our installers arrive.

For more detailed planning information, download our Builder’s Guide.

Click here to download

Each door opening must be built exactly to the approved Lift Shop drawing. All openings must be square, level, and plumb from floor to ceiling.

Lift doors are anchored directly to the building structure. Solid supports must be in place before installation.

Builders can finish doors to blend seamlessly with the wall or joinery. Follow these limits to ensure smooth operation and long-term reliability.

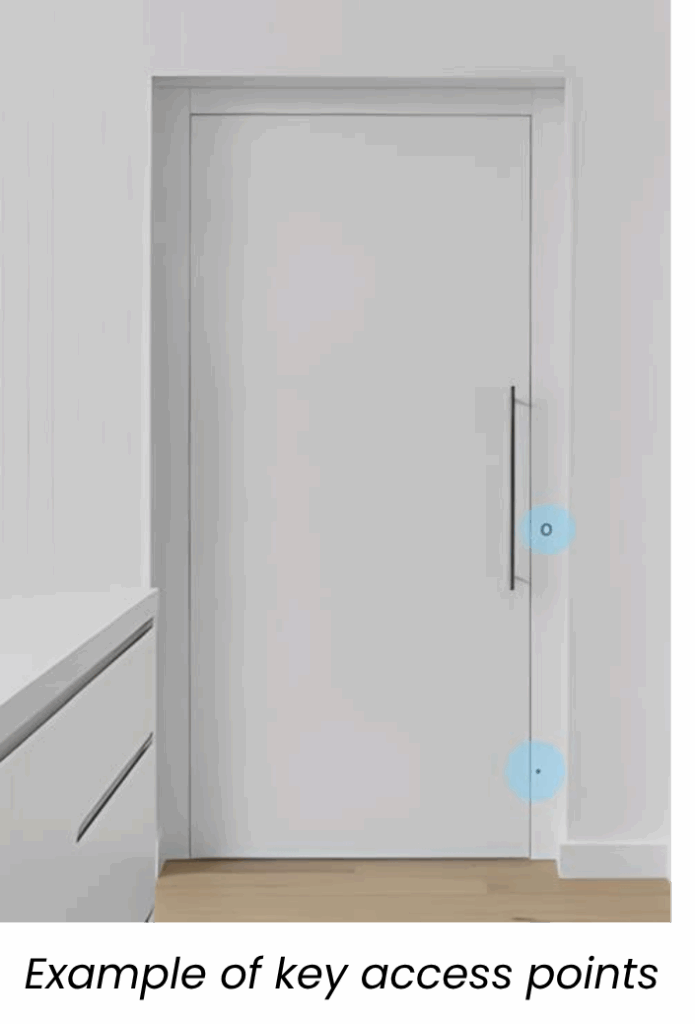

Each landing includes a call button plate and emergency key access point. Space and access must be left clear for these components.

Correct spacing and alignment ensure reliable performance and a clean finish.

| Component | Requirement | Note |

|---|---|---|

| Door swing clearance | Door must open freely without obstruction | Check before final cladding |

| Floor-to-sill transition | No lip or step greater than 2 mm | Builder to level to FFL |

| Wall alignment | Consistent wall depth and finish thickness | Match across every floor |

| Between-door walls | Line and finish visible shaft surfaces | Visible during lift operation |

| Shaft reveal | No services or recesses | Smooth and flush for sealing |

Before Lift Shop installation, confirm all site conditions meet the approved drawings and requirements:

Once installation starts, no further structural or finishing changes can be made without Lift Shop approval.

Image suggestion: Completed landing with flush door finish.

For a premium finish, consider:

Lift Shop can guide your builder or designer on suitable materials and tolerances before work begins.

Practical lift planning guidance for builders and project teams, covering shaft requirements, door preparation and key considerations before construction.

A curated gallery below showcases correct door framing, finished openings, custom button plates, and completed installations for builder reference.