When it comes to installing a home lift, the shaft is where it all begins. It’s the structural core that defines performance, safety, and long-term reliability, the foundation for a smooth, quiet, and compliant lift system.

At Lift Shop, most clients’ builders construct the shaft in accordance with our engineering drawings and specifications. This ensures every project meets the required tolerances, load capacity, and building code compliance.

For projects where a complete frame is preferred, we can supply the “Bones Only Shaft by Lift Shop”, a certified internal steel structure that your builder can clad and finish.

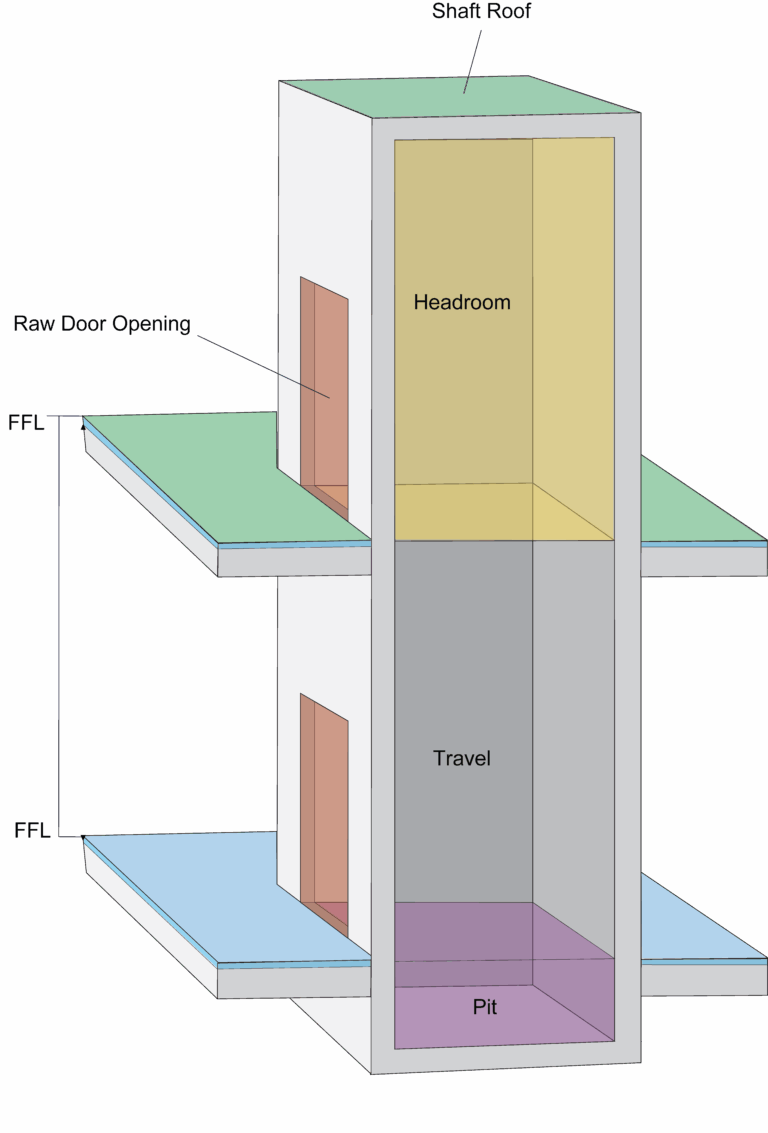

A lift shaft (or elevator hoistway) is the vertical enclosure that houses the lift cabin, rails, and drive system. It supports structural loads and ensures safe, stable travel between floors. In residential projects, it’s designed for both functionality and architectural integration.

For more detailed planning information, download our Builder’s Guide.

Click here to downloadIncreasingly, clients are choosing to build the lift shaft during construction, even if the lift will be installed later. This approach offers flexibility and long-term value.

Lift Shop provides shaft drawings and specifications so your builder can construct a compliant,

future-ready shaft now, ensuring a seamless installation when you decide to proceed with your lift.

In most cases, your builder constructs the shaft following Lift Shop’s engineering drawings and requirements.

This method keeps the process efficient and cost-effective while ensuring compliance with all lift standards.

Lift Shop supports your builder with coordination packs, structural load data, and direct technical assistance.

A qualified structural engineer must confirm load capacity before installation.

| A/E Series | A/E Series with Standoff Bracket | C Series | |

|---|---|---|---|

| RHS Cross Member Size | 100x100x5mm | 200x100x5mm | 200x100x5mm |

Spacing between horizontal cross members will be in the signed final drawing.

For all lift types with or without stand off brackets the vertical posts are to be 150x150x5mm

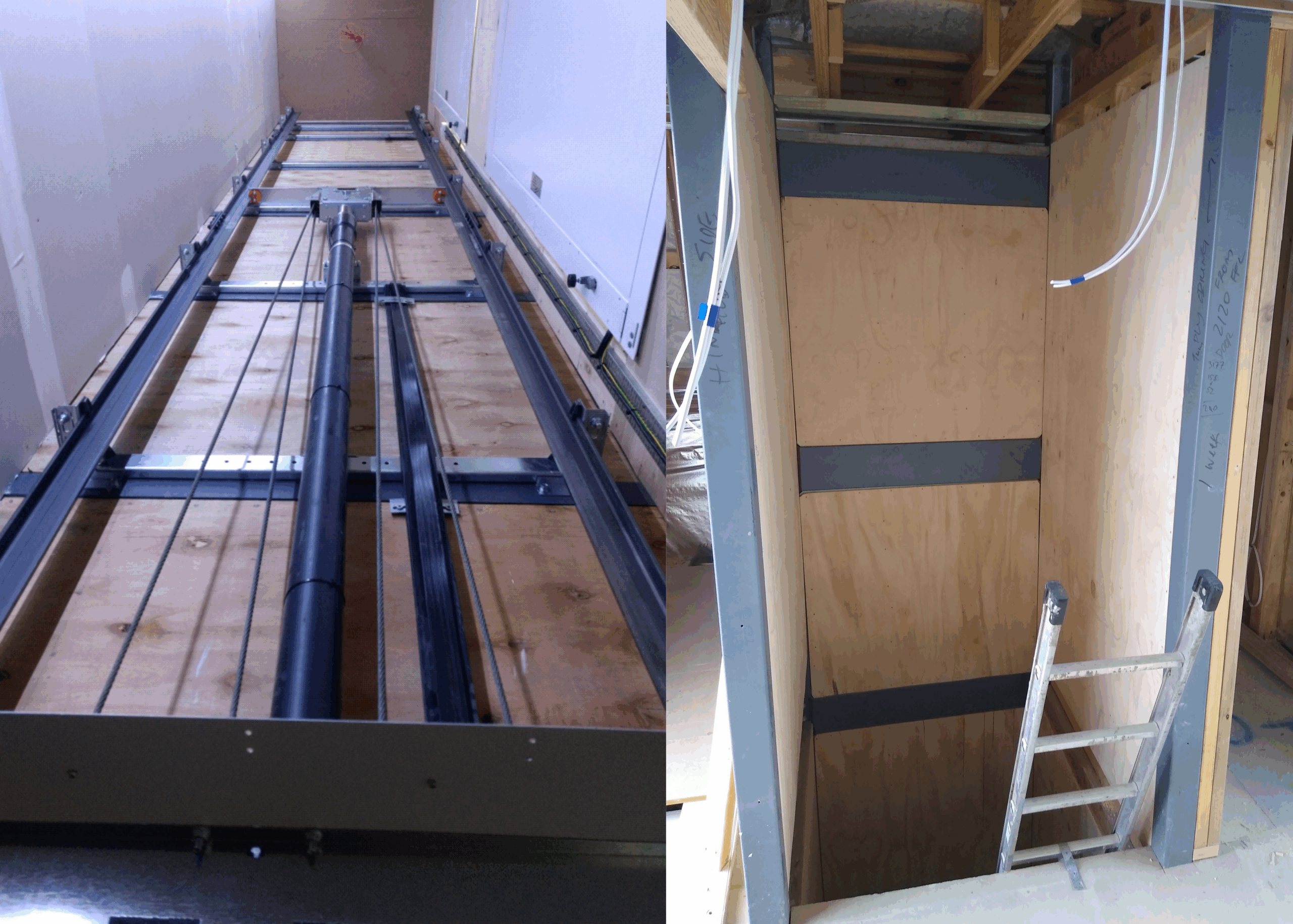

For homes where a traditional load-bearing shaft is impractical, Lift Shop can supply a self-supporting steel shaft structure, the same framework referred to as our “Bones Only Shaft”.

This pre-engineered structure forms the lift’s complete internal skeleton, eliminating the need for the builder to create a load-bearing shaft from scratch.

Practical lift planning guidance for builders and project teams, covering shaft requirements, door preparation and key considerations before construction.

Whether it’s a stunning coastal view or a lively living space, many clients love the experience of travelling in a lift surrounded by glass, bringing light and visibility into the journey.

While Lift Shop offers a full range of glass shaft options (steel and aluminium framed),

many builders choose to design and construct their own glass enclosures for a fully customised architectural finish.

Glass shafts are constructed by qualified builders to Lift Shop specifications. We integrate our lift systems seamlessly within your chosen glass shaft design.

The results are remarkable, bespoke glass shafts that integrate seamlessly with the home’s design while maintaining Lift Shop’s mechanical precision and safety standards.

| Requirement | A Series | C Series | E Series |

|---|---|---|---|

| Pit Depth | 150 mm | 150 mm | 270 mm |

| Headroom | 2600 mm | 2550 mm | 2750 mm |

| Load-Bearing Wall | Yes, drive side | Yes, drive side | Yes, drive side |

| External Cladding | 3 mm builders ply | 3 mm builders ply | 3 mm builders ply |

| Internal Walls | Non-penetrable or timber with 20 mm ply | Non-penetrable or timber with 20 mm ply | Non-penetrable or timber with 20 mm ply |

| Drainage | Not required | Not required | Not required |

Explore both Sliding Door & Swing Door Lifts

Yes. Lift Shop regularly assists homeowners who want to build the shaft during construction and add the lift later. A cost-effective and future-proof solution.

It’s a galvanised steel structure supplied by Lift Shop that supports the lift without a load-bearing wall. Your builder then encloses it for safety.

Yes. We offer glass shaft solutions or can work alongside your builder to integrate a custom glass design.

Your builder, following Lift Shop’s engineering drawings and requirements. We provide full support during construction.

The lift shaft defines your lift’s safety, comfort, and visual integration.

Whether constructed by your builder or supplied as a self-supporting Bones Only Shaft,

Lift Shop ensures compliance, precision, and effortless coordination from start to finish.

Lift shafts must comply with fire-rating requirements set out in the National Construction Code (NCC 2022). These requirements depend on whether your building is residential or commercial, the number of storeys, and the occupancy classification.

In general, residential lift shafts must have fire-rated doors and walls that resist flame and smoke penetration for a specified period (typically FRL 30/30/30 or equivalent). We consult with your structural engineer and building certifier to confirm the specific fire-rating requirements for your project.

Load reaction forces are the structural forces that the shaft floor must safely support when the lift operates. These forces include the weight of the lift cabin, counterweight (if applicable), passengers, and mechanical equipment, plus dynamic forces from acceleration and deceleration.

Load values vary depending on the lift series, capacity, and configuration. We recommend that your structural engineer confirm load capacity through calculation or testing rather than relying on generic assumptions.

Internal shaft dimensions depend on your chosen lift series (A-Series, C-Series, or E-Series), cabin size, and door type (swing or sliding). The A-Series cabin is approximately 1000 x 1000 mm or 1000 x 1200 mm. The C-Series cabin is compact at around 900 x 1000 mm. The E-Series is larger, accommodating up to 7 persons.

We provide detailed engineering drawings specific to your project showing the exact internal shaft dimensions required. These drawings are produced during the design phase and must be approved by your builder before shaft construction begins. Our team works closely with your architect to ensure the shaft dimensions integrate seamlessly with your home layout.

A non-penetrable wall means the shaft walls must be continuous, solid, and without holes, gaps, or weak points that could allow the lift cabin, ropes, or counterweight to break through in the event of a fault or accident.

Common compliance mistakes include: drilling holes in walls for electrical conduits without proper reinforcement or approvals; installing lightweight cladding or drywall without structural backing; leaving gaps between wall panels; or constructing walls from single-layer materials without adequate thickness (minimum 190 mm solid reinforced blockwork or equivalent). We review your builder’s construction plans and conduct inspections to ensure non-penetrable compliance before installation.

Space requirements depend on your chosen lift series and door type. The A-Series requires approximately 1000 x 1000 mm of internal space (or 1000 x 1200 mm for a larger cabin). The C-Series is more compact at around 900 x 1000 mm. The E-Series is larger, designed for 7 persons.

Beyond the cabin footprint, you also need adequate pit depth (150 mm for A-Series, 130–230 mm for C-Series, 270 mm for E-Series) and headroom above the top landing (2400–2750 mm depending on series and configuration). We assess your available space during the site visit and advise whether a particular series will fit, or recommend alternatives if space is extremely constrained.

Yes. Lift Shop lifts can be installed in timber-frame shafts, provided the timber is properly reinforced with structural engineering to meet load and durability requirements. Timber shafts must be constructed with adequate thickness and bracing to ensure they are non-penetrable and load-bearing.

Whether timber is appropriate depends on the local building codes, the lift series and capacity you choose, and your site conditions. We review timber shaft designs with your structural engineer and building certifier before construction. In many cases, masonry or concrete shafts are simpler and require less reinforcement, but timber is viable if designed correctly.

Yes. The lift pit must have adequate drainage to prevent water accumulation, which can damage mechanical components and create safety hazards. A sump pump or drainage system is typically required, particularly in areas with high groundwater or heavy rainfall.

Ventilation in the pit is not always necessary, but good air circulation helps prevent corrosion and moisture build-up. Waterproofing measures should be applied to pit walls and floors to protect against seepage and damp. We coordinate with your builder and structural engineer to design an appropriate pit drainage and waterproofing strategy specific to your site conditions and local building codes.

The Bones Only Shaft is a pre-engineered, pre-fabricated internal steel structure with a galvanised finish that we supply as a certified assembly. Your builder then clads all four sides with approved materials (masonry, concrete, timber, or composite), creating a complete shaft.

Choose Bones Only when your builder prefers to handle all finishing work or when you want guaranteed structural certification before cladding begins. Advantages include reduced on-site welding, consistent quality control, and faster construction timelines. The builder-built alternative gives your builder full responsibility for structural design and execution. We discuss both options during the planning phase to determine what suits your project best.

Your building certifier or structural engineer inspects the completed shaft and signs off that it meets all relevant Australian Standards, building codes, and safety requirements before our installation team begins work. This sign-off confirms that pit depth, headroom, wall strength, non-penetrability, and all other parameters are compliant.

We work closely with your building certifier throughout the design and construction phases. Our team provides engineering drawings and specifications to your certifier, and we participate in any inspections or reviews they require. This collaborative approach ensures that when sign-off occurs, the lift installation can proceed smoothly and on schedule.

Construction tolerances specify how precisely the shaft dimensions must match the design drawings. For lift shafts, the most critical tolerances are vertical travel and finished floor level (FFL) accuracy, which must be maintained to within plus or minus 5 mm (+/-5 mm).

This tight tolerance ensures that the lift cabin aligns smoothly with floor openings at each level and operates safely. Other tolerances apply to wall plumb (vertical straightness), wall flatness, and pit floor levelness. During construction, your builder should verify dimensions regularly and make adjustments as needed to stay within tolerance. Our installation team conducts final dimensional checks on site before installation begins.

Lift shaft construction costs vary widely depending on your location, building type, chosen materials (masonry, concrete, steel, timber), the Bones Only option versus builder-built, required fire-rating, and structural complexity. A typical residential shaft might cost $15,000 to $40,000 or more, but this is highly site-specific.

We recommend obtaining quotes from your builder or a specialised lift shaft contractor based on the engineering drawings we provide. [VERIFY: Specific shaft construction costs not published on liftshop.com.au — confirm typical range with Lift Shop team]. Our team can advise on cost-effective approaches and help you understand the factors that influence your shaft budget.